April Insights from Connect 2 Cleanrooms

It’s been a busy month for Connect 2 Cleanrooms, delivering projects across the UK and Europe, and celebrating a prestigious award win 🏆

We protect critical processes for a diverse range of sectors around the world. In 23 years, we’ve become a trusted partner to over 6,000 clients worldwide. By supporting the full cleanroom lifecycle with integrated cleanroom services, we provide contamination control way beyond the commissioning of your cleanroom

By making your process requirements our priority, we build contamination control solutions that manage risk. As cleanroom specialists, we understand the complex and critical nature of meeting regulatory requirements and—most importantly—you can trust us to get you there.

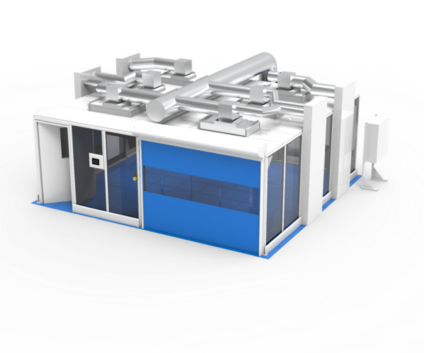

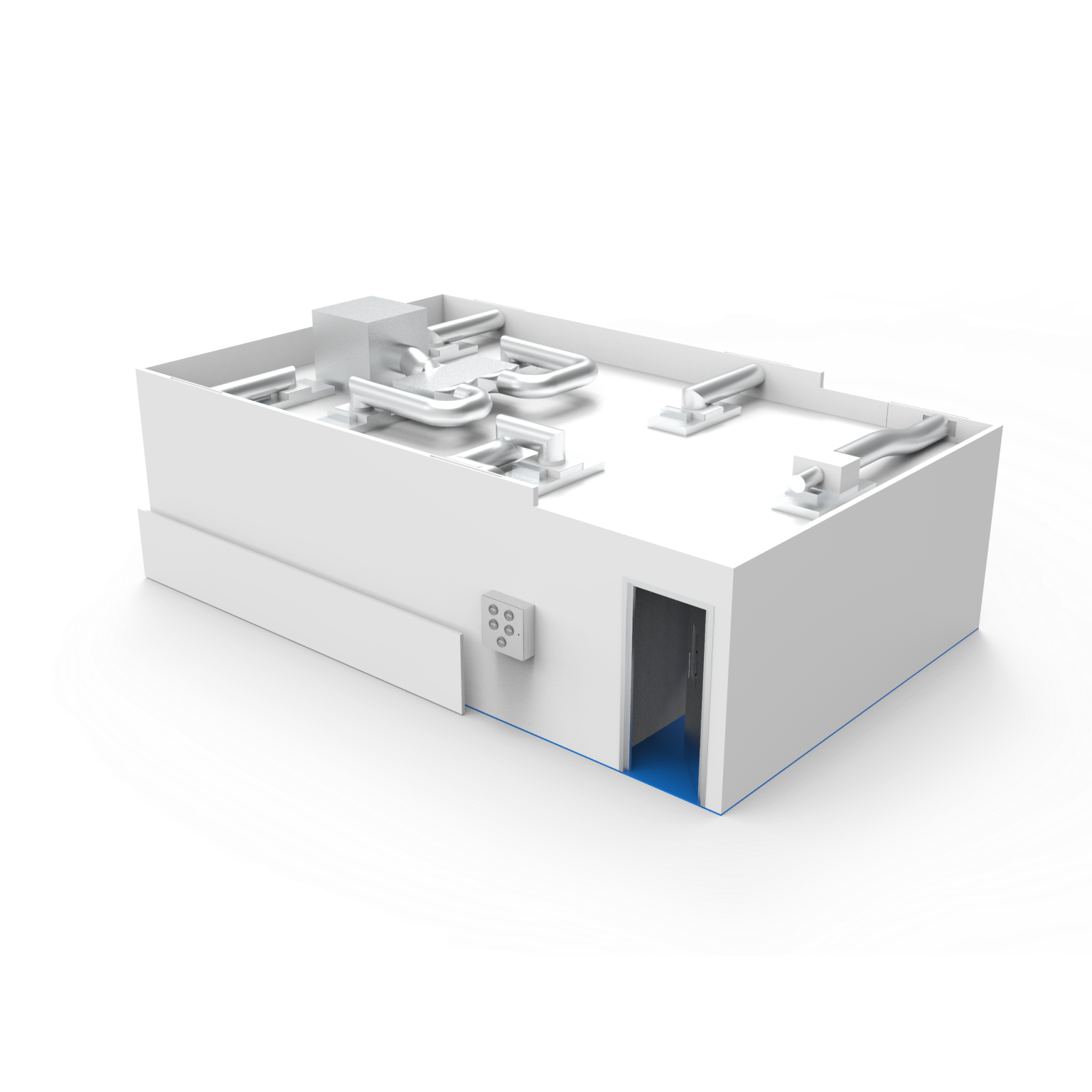

Developing the most appropriate cleanroom to transform your production is our passion. Our scalable and connected cleanrooms provide protection and regulatory compliance for our client’s critical processes.

Connect 2 Cleanrooms offers a full range of cleanroom design & build services. From design only packages to full architectural fit-out services, we have specialist, in-house expertise to help you at every stage.

The biggest contamination risk in a cleanroom is people and products. Our CPD-certified ISO and EU-GMP cleanroom training courses educate delegates on protocols and contamination control.

With a tailored cleanroom qualification testing schedule, Connect 2 Cleanrooms will certify the class or grade of your cleanroom facilities and localised clean air devices.

Our consumables and equipment division, Cleanroomshop, supplies a varied portfolio of products from leading brands, along with supportive pricing and delivery mechanisms. All with the highest levels of service.

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!