Humidity-Controlled Dry Rooms

A humidity controlled dry room is a specialist production area with industrial dehumidification to maintain the air at low dewpoints (dp) for moisture-sensitive manufacturing processes or research. A dry room dew point is generally minus 30.0°Cdp and below, or less than 1% relative humidity (RH). The ultra-dry air creates an ideal environment for operations such as battery production.

An ultra-low humidity (dewpoint) room gives a consistent environment to investigate issues and produce a stable baseline for sensitive materials and processes. Within R&D applications, a dry room can help to determine whether it is the synthesis of the materials or the deposition processes that causes defects.

Benefits of controlled humidity levels:

- Lowers the risk of electronic failures through moisture damage

- Protects materials from corrosion or damage caused by sensitivity to low relative humidity

- Prevents the degradation of hygroscopic materials

- Reduces bacterial growth

What is dew point?

Dew point (dp) is the temperature that a volume of air reaches when it becomes saturated with water vapour, causing dew to form. It is used as a standard parameter to determine humidity control in an environment like a dry room.

Dry room specifications

Let’s look at the dew point in a typical environment to demonstrate how ultra-dry the air is in a dry room. Comfort cooling is usually 20-22°C and 50% RH, which translates to approximately 9.3°Cdp.

Now let’s look at the requirements for battery production, which is a typical use of a dry room. Because of the sensitivity of their materials, solid-state battery dry rooms may need humidity controlling to minus 30/35.0°Cdp at the point of return. In comparison, a dry room for lithium battery needa a greater humidity control of around minus 50.0°Cdp at the point of return.

These examples illustrate a vast difference between the requirements of a typical environment and an application that needs a dry room. A combination of an HVAC design, an airtight envelope system, and process controls produce the conditions for a dry room.

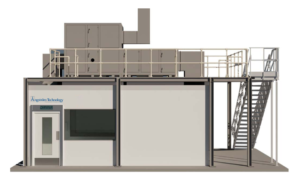

Speak to dry room manufacturers Angstrom Technology about battery dry rooms

Angstrom Technology partners with DRYAIR to deliver ultra-low dewpoint HVAC design for clients. Speak to us today about your dry room project.

READY TO START A NEW PROJECT?

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE