Custom-built ISO Cleanrooms

Angstrom Technology provide world-leading organisations with custom-built ISO cleanrooms. Our modular cleanrooms create controlled manufacturing conditions, to help you produce reliable and consistent products.

ISO cleanroom construction

Developing the most appropriate ISO cleanroom construction to transform your production is our passion. In the design phase, our team will review operational requirements, workflow optimisation, running costs, and any applicable building regulations. The result? A cleanroom custom-built for your process.

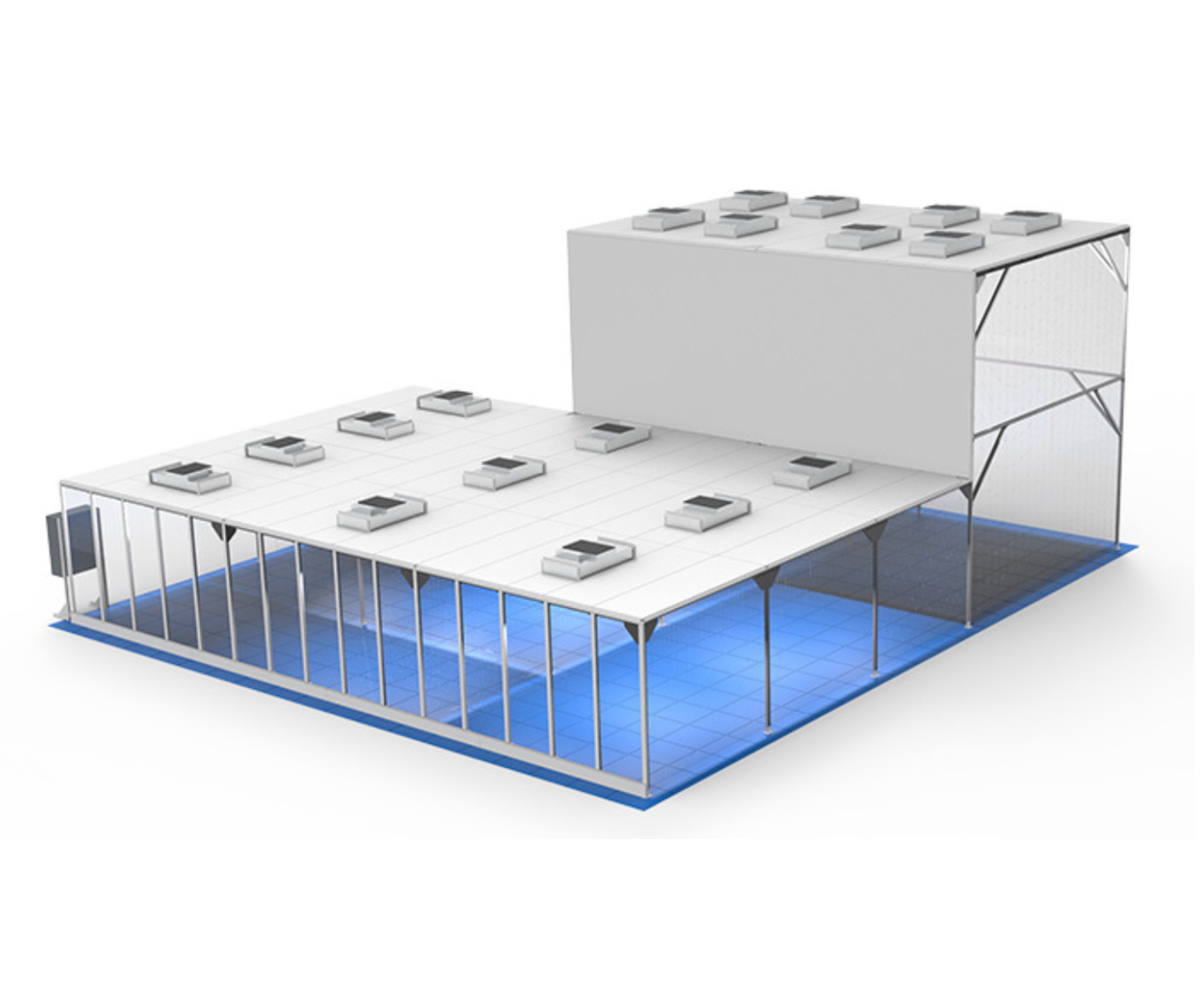

Monobloc cleanrooms

Monobloc panels with an insulative core create a flush or semi-flush wall construction for processes demanding tighter control of environmental conditions.

Hardwall cleanrooms

Hardwall PVC or PETg panels, attached to a powder-coated mild steel frame create a high-integrity modular cleanroom wall construction. Ideal for relocation.

Softwall cleanrooms

Softwall panels hung from a powder coated mild steel frame create the most economical type of modular cleanroom wall construction. Ideal for relocation.

ISO cleanroom manufacturers

Structural and mechanical ISO cleanroom manufacture is essential to achieve functional and regulatory compliance. Each one of our cleanrooms features an air handling system designed to perform with controlled running costs.

Take a look at the ways we can custom-build your perfect cleanroom solution.

Scalable

Centralised or decentralised air handling

ECO control system

Flooring choices

Lighting

ISO cleanroom design & build projects

Our complete systems achieve ISO classification. Not only that, but our ISO cleanroom design & build projects can also meet any applicable international engineering and building standards and regulations.

We’ve developed proven envelope solutions and reliable cleanroom HVAC designs for many applications. Over 50 cleanroom projects have been completed in the last 12 months alone, including:

- 6,000m² cleanroom in Cardiff for healthcare production

- 250m² cleanroom in Sunderland for electronic battery production

- 325m² cleanroom in the Midlands for space-related R&D and manufacturing

- 1,600m² cleanroom in Southampton for solid-state battery production

Cytiva supports global biopharma industry with 6,000m² cleanrooms in Cardiff, Wales

Industry: Healthcare | Pharmaceutical

Wall type: Monobloc – fully flush

Classification: ISO 7

182m² CBD products cleanroom for Orange County CBD

Industry: Healthcare

Wall type: Hardwall

Classification: ISO 7

High-purity pipe fabrication cleanroom with ISO 4 pods

Industry: Engineering – Manufacturing

Wall type: Softwall

Classification: ISO 6 & ISO 4

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE