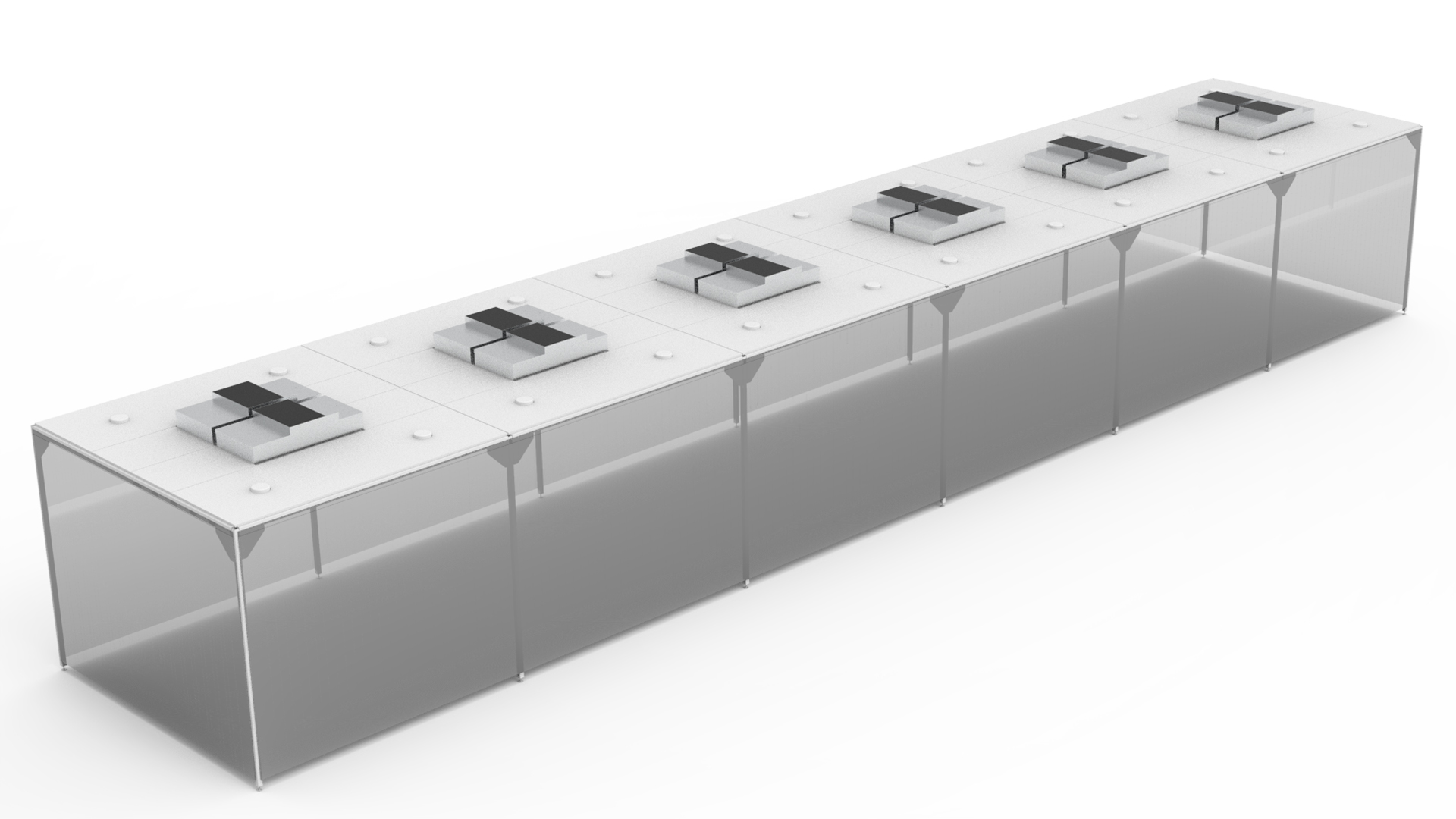

Assembly Cleanroom for Panasonic Head Up Displays Production

With an established relationship supplying consumables to their existing cleanroom housing 200 operatives, Panasonic knew C2C’s reputation for quality. When the time came for them to increase cleanroom capacity, C2C were approached.

Key facts

61.2m² cleanroom facility

For the production of head up displays

Softwall cleanroom

Cost-effective & installed over existing equipment

Tight time-scales

Successfully delivered in under 7 weeks

Modular design

Can be extended to facilitate future growth

The requirements

Panasonic needed to increase cleanroom capacity for the production of its Head up Displays (HUDs) for one of the OEMs in the Czech Republic.

The HUDs work by projecting critical information such as sat nav instructions on the windscreen of cars, reducing the need for a driver to divert their attention from the road. As an optical product, it is important to control contamination to avoid defects on the electronic parts and on the device itself, so the units are ISO cleanroom assembled.

The solution

With an established relationship supplying consumables to their existing cleanroom housing 200 operatives, Panasonic knew C2C’s reputation for quality. When the time came for them to increase cleanroom capacity, C2C were approached.

We delivered an ISO Class 8 softwall cleanroom that, due to the sensitive nature of the products, had ESD protection built in.

The results

Panasonic had tight time-scales so there was no room for project creep. C2C successfully delivered the project in under 7 weeks, meeting Panasonic’s needs and even finishing the install ahead of schedule.

Panasonic commented that the communication between the account management, project planning and installation teams was excellent and the good organisation was a key factor in the successful on-time project delivery.

Coming from automotive manufacturing where perfection is naturally demanded, I look to establish long term relationships with global partners. It was not a supplier / customer relationship between Panasonic and Connect 2 Cleanrooms – it was like 1 team. A perfect match!

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE