ISO Class 7 Cleanroom with Full Lifecycle Service

We have supported MacTaggart Scott with setting up a 5 year service contract which includes annual validation visits and emergency call out cover for peace of mind.

Key facts

59m² cleanroom for precision part manufacture

ISO Class 7

Efficient install

Fully-fitted with furniture and cleanroom trained

What did our client need?

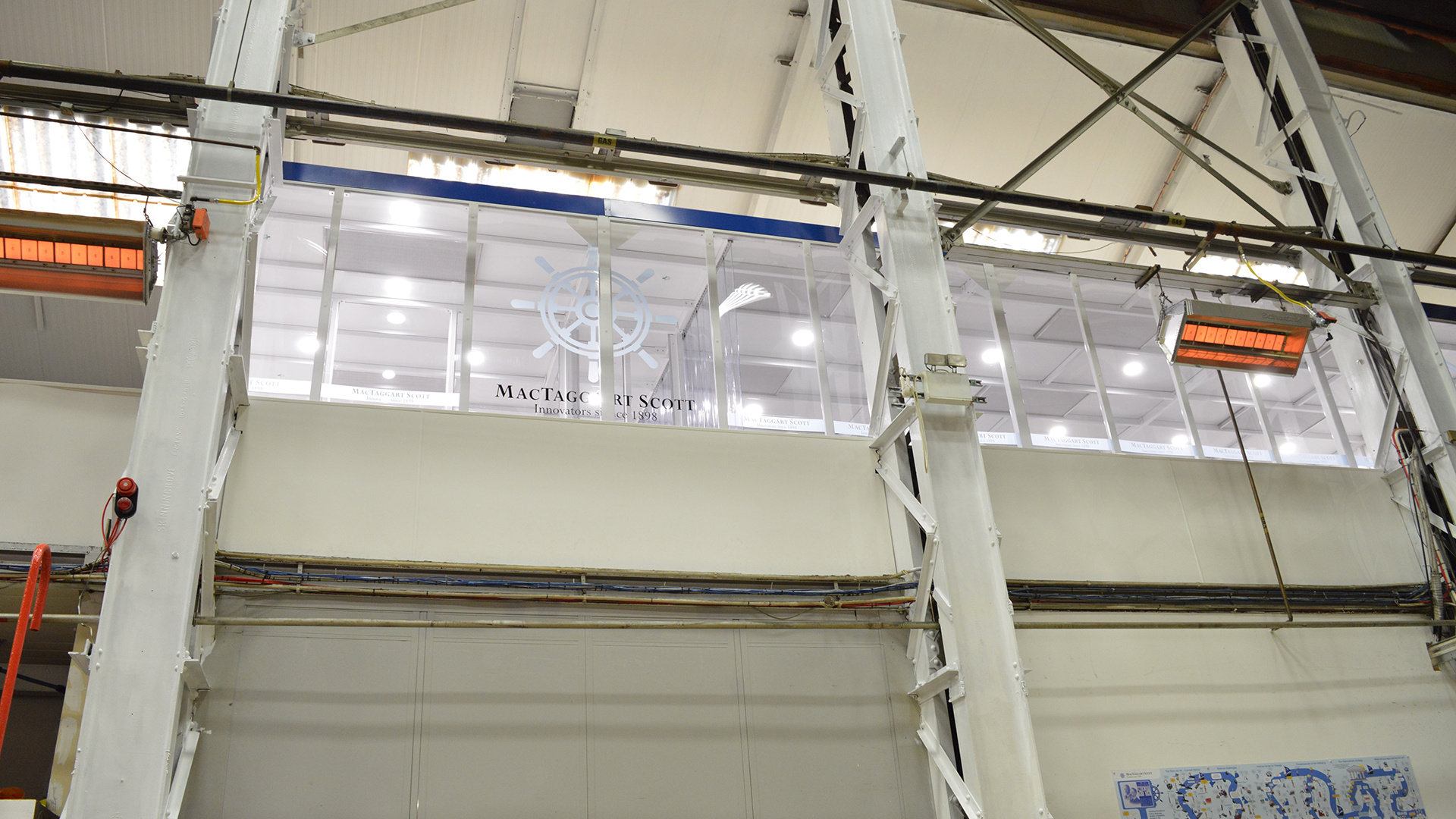

When MacTaggart Scott was awarded a new contract for a product with cleanroom requirements, a review of their existing facility and process prompted them to look at opportunities for a new cleanroom. After approaching 3 cleanroom companies, they appointed Angstrom Technology because of our capability to provide a bespoke solution and their cleanroom lifecycle support.

“Angstrom Technology was the only company we approached that offered a bespoke cleanroom solution and we could have everything that we could possibly want. The additional lifecycle support with After-Sales, Consumables and Cleanroom Training, really helped improve my cleanroom knowledge – their support has been invaluable,” said our contact at MacTaggart Scott.

How did we help our client?

We helped MacTaggart Scott to understand the ISO Cleanroom Standard and to build an appropriate User Requirement Specification (URS). For the assembly of precision machine parts and bearings, clients expect cleanroom production and the new ISO Class 7 facility is now opening up more opportunities through improved quality and cleanliness. The review of the process has also generated additional efficiencies and MacTaggart Scott is now benefitting from reduced overall costs and increased process confidence.

Our contact at MacTaggart Scott also commented on the install; “it went really well and the site lead did a great job of leading the project. The team started early in the morning and had long days, giving me an update on where they were up to each day,” he continued. “The organisation of the project was really impressive. Timelines were stuck to and the whole thing went very smoothly.”

Cleanroom lifecycle: fit-out, training and validation

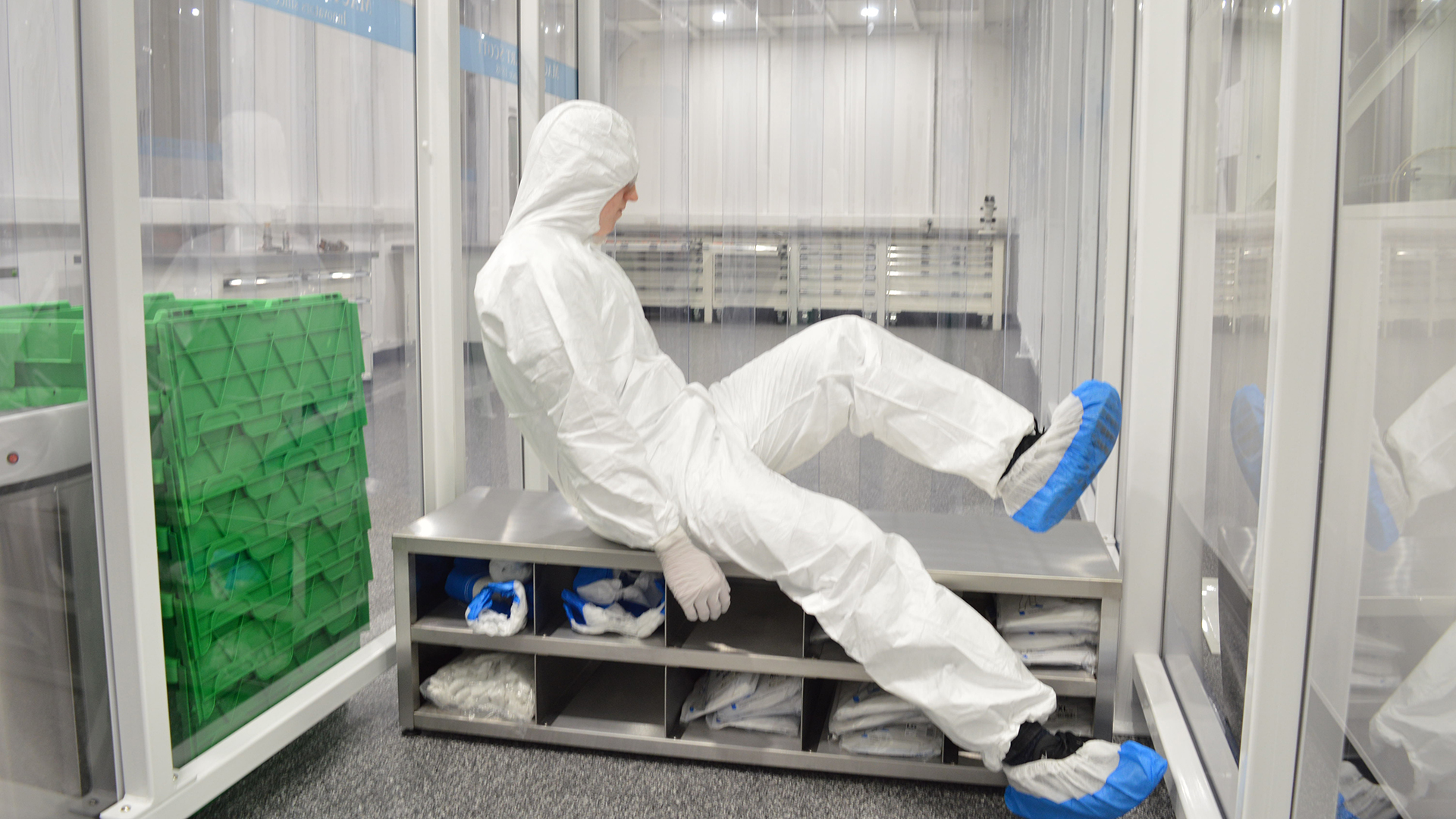

MacTaggart Scott took a lot away from the cleanroom training that we delivered, particularly the gowning and monitoring presentations. It has prompted the introduction of new kitting boxes for the cleanroom and workshops to reduce cross contamination.

Following the presentations, MacTaggart Scott saw the value in an effective cleanroom change area layout and purchased a variety of items from Cleanroomshop – from a step over bench to cleanroom clothing. “The step over bench works as a physical barrier, as well as providing storage and helps us to put our overshoes on. We can also store the Tyvek gowns tidily in the change area with the coat hooks that we bought. The quality is fantastic”, our contact added.

“We also bought a particle counter to allow us to meet our customer requirement of conducting weekly particle counts.”

We have also supported MacTaggart Scott with setting up a 5 year service contract which includes annual validation visits and emergency call out cover for peace of mind.

The full lifecycle that Angstrom Technology provides makes it really easy to navigate around all of the different services that we need to use. They are really price competitive, have a great product range and it is easy to navigate around www.cleanroomshop.com.

This support was the biggest reason for purchasing from Angstrom Technology – the guidance with the room, service contract and the consumables has saved us a lot of hassle. This has been a massive project and the extra support and reassurance has been really special.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE