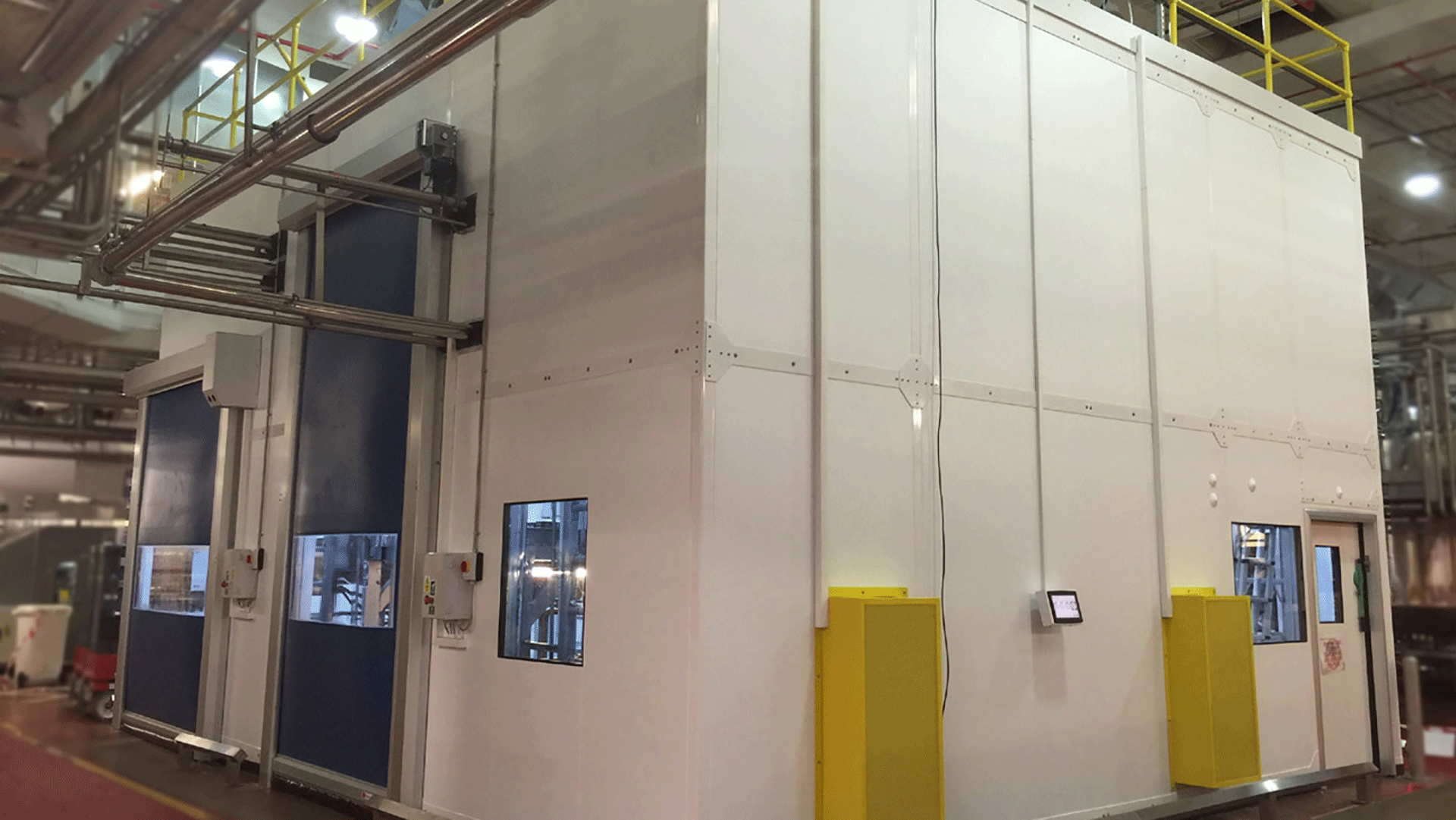

ISO 8 Monobloc Partition System with HEPA-lite™ Canopy

Our client, a high street pharmacy brand, required an ISO 8 clean room that would protect the production of moisturising creams, to prevent contamination from other areas entering the mixing vessel.

Key facts

Installed in a GMP facility

52m² with height to accomodate mixing vessels

Sliding canopy for overhead access to machinery

Walkable ceiling and roller doors

What did the client need?

Our client, a high street pharmacy brand, required an ISO 8 clean room that would protect the production of moisturising creams, to prevent contamination from other areas entering the mixing vessel.

How did the client benefit?

We designed a cleanroom with monobloc partition system structure, that was installed to accommodate existing equipment and processes – with a sliding canopy for overhead access, a walkable ceiling and roller doors.

How did we help the client?

The client now benefits from accessible and flexible clean production in their manufacturing plant. Important measures were taken to reduce cross contamination, such as low level extraction.

“This cleanroom was installed in a GMP facility. The yellow units you can see at the bottom of the room are HEPA exhaust filters, so no contaminated air passes out into the external environment.”

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE