Cogent Technology experience significant productivity gains with Rapidbloc Cleanrooms

Two Rapidbloc cleanrooms were designed and built in just 8 weeks – including validation – to ISO 14644-1 class 7 for Cogent Technology to serve its clients with world class manufacturing.

Key facts

Two 60m² Rapidbloc Cleanrooms

Designed and built in just 8 weeks

Installed within facility fit-out programme

Production was not interrupted

ISO class 7

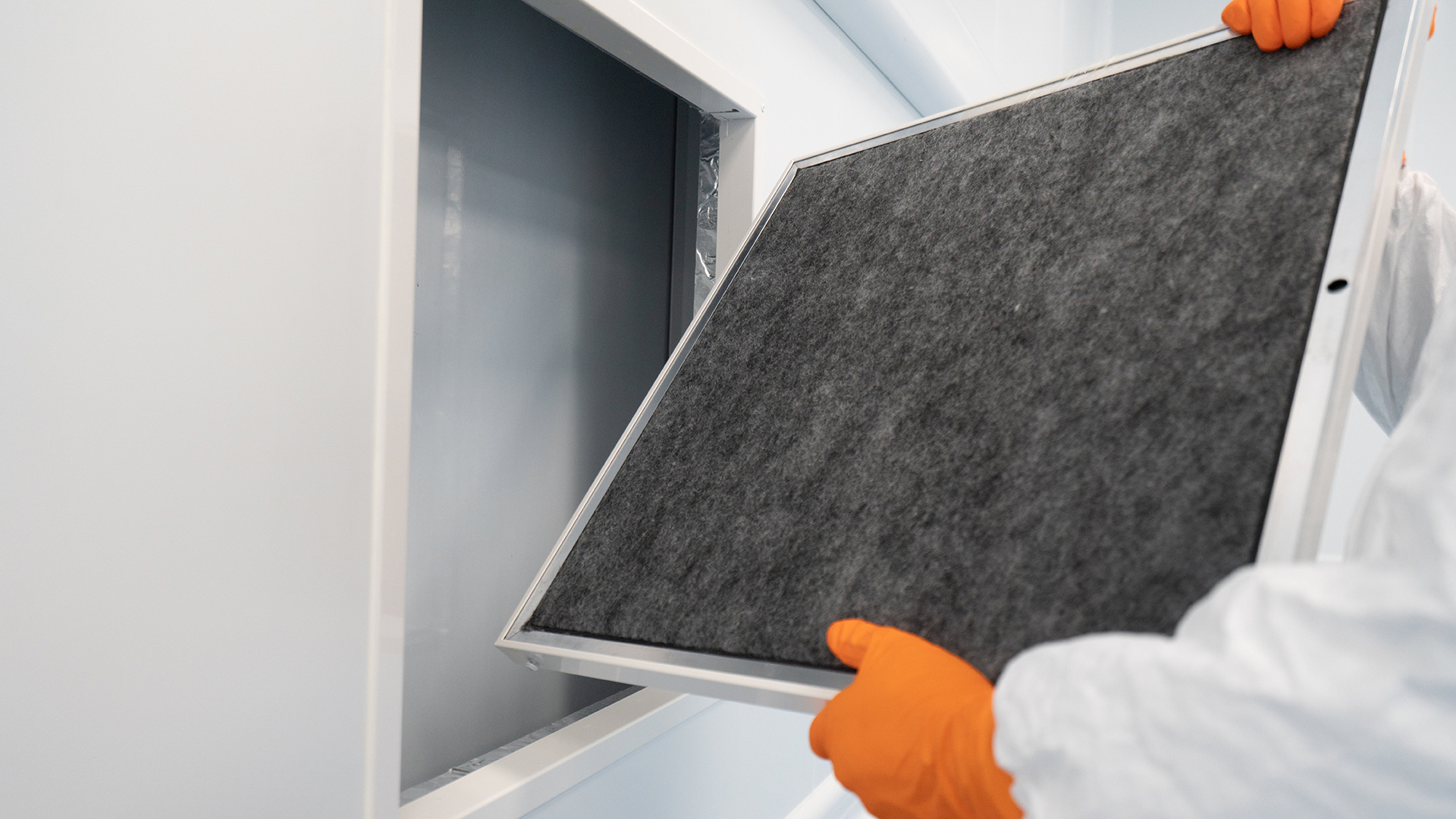

Achieved through HEPA filtration, air return and pressure stabilisers

Cleanroom LED lighting

Plus coved cleanroom flooring

What did our client need?

Cogent Technology has moved into a new 80,000ft² facility in Felixstowe, to serve its clients with world class manufacturing. The new facility features state of the art production lines and Cogent required two bespoke cleanrooms that were able to be installed within its wider facility fit-out programme and so production was not interrupted.

How did we help our client?

Connect 2 Cleanrooms delivered two 60m² Rapidbloc Cleanrooms.

Specification:

- HEPA filtration

- UltraTech Versatile cleanroom panels

- LED lighting

- Coved cleanroom flooring

- Air return and pressure stabilisers

Clean production will enable Cogent to grow its product offering and expand services to clients with consumables and accessories that complement existing PCB assembly product ranges.

Rapidbloc Cleanrooms have been developed by Connect 2 Cleanrooms (C2C) to meet the urgent critical demands of some of the world’s fastest moving industries, such as healthcare and advanced manufacturing.

How did our client benefit?

The two Rapidbloc cleanrooms were designed and built in just 8 weeks, including validation to ISO 14644-1 class 7. A monobloc cleanroom project of this scale would usually have a lead time of up to 4 months, whereas Rapidbloc Cleanrooms generate significant productivity gains to enable a faster return on investment. Rapidbloc cleanroom layouts are fully configurable and as parts are shipped from stock from C2C’s warehouse and distribution hub, on-site assembly is fast and efficient.

This investment will not only enable Cogent to meet our current clients’ needs, but also position the team to facilitate the provision of associated device consumables capacity as med tech businesses rethink their supply chain strategies in light of changing attitudes to sourcing.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE